-40%

1998 HOMAG KR 77/A20 EDGEBANDER

$ 7128

- Description

- Size Guide

Description

DetailsYear:

1998

Make:

Homag

Model:

KR 77/A20

Model # 0-200-08-32950

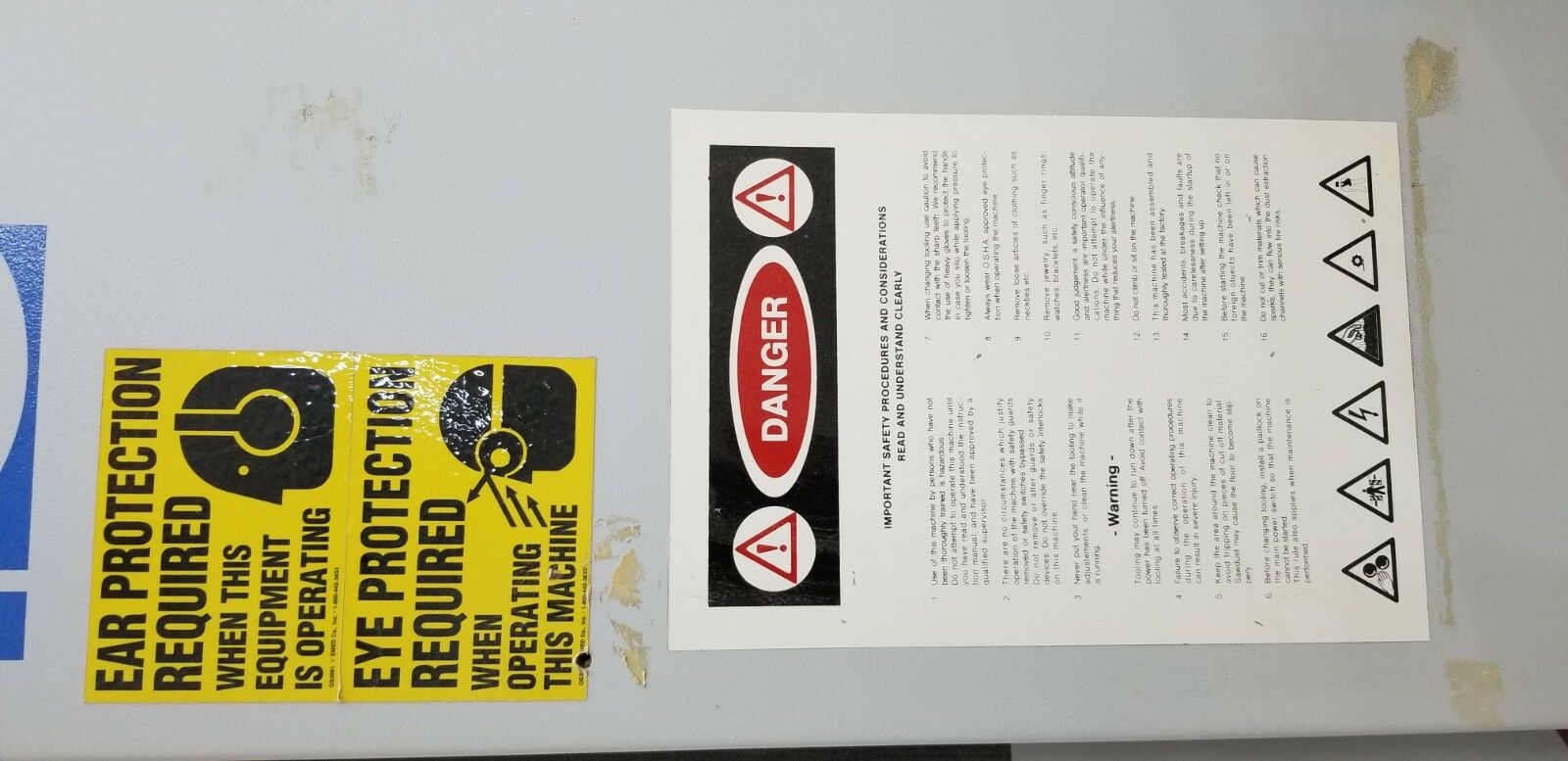

HOMAG KR-77/A20/S2 ... Production Edgebander with Pre-Milling and ATC (8 Station) Corner Rounding Unit -- Capacity / SpecificationsEdge thickness 0.4 - 20 mm, min. panel width 55 mm (2-1/4"), panel thickness min/max 12 - 60 mm. -- In-feed Section Equipped With: -- Squaring In-feed Fence, ... THK guided and air cylinder operated sliding fence on work-piece outrigger support side to align the front-edge of a work-piece to allow squaring up of a panel with the Pre-Milling Unit. -- Pre-Milling Unit, 2 x 3 Kw motors, (1) spindle with jump capability and digital adjustable in-feed fence. -- Edge Magazine, automatic combination strip/coil edge magazine for coil material up to 3 mm thickness, strip material for up to 20 mm (3/4") solid wood banding; -- Glue System "QA 34", Quick Melt EVA (Hot Melt) with pre-melt hopper feeder & roller applicator (reversible); -- Pressure Section, servo controlled with (1) large dia. driven & (6) idle rollers -- Workstations Include: -- End Trimming, double end trim to cut excess edge on the front & back of the panel with remote swivel control. -- Rough/Flush Trimming, top/bottom, trimming (2 x 1.5 Kw motors) -- Multifunction Trimming Unit, with 2 x 0.55 Kw motors, Fine/Corner Rounding Trimming with automatic 8-station tool changer for changing profiles/radiuses on the fly (this station functions as Fine Trimming AND Corner Rounding unit) -- Profile Scraping Unit, with servo motors for in/out, copy wheel & different profile knifes positioning. -- Empty Position, for potential retrofitting a flat top & bottom glue scrape unit. -- Release Agent Unit, top bottom spray unit for easy clean-up of potential residues. -- Buffing Unit, top & bottom oscillating and adjustable in x-y-z directions for the most effective buffing results.Controller: -- HOMATIC "NC 21" Line Control, controller features real-time "OS9" operating system, functions in Windows Environment; PLC for (40) working programs, each with (160) functions for remote control of processing units; keypad w/LCD display, fault diagnostic, etc. -- Complete with, electronic DC brakes on all trim motors, sound cabins for all trim workstations

The unit was is in good working condition when we bought it, Never had time to bring it to the shop and install it, currently unplugged, selling it AS IS. Customer is responsible for pick up, we will help with loading. Please call for more details 864-58-9165 ask for Andrey